i actually bought this player sometime last year from a seller on ebay without having any prior knowledge on both the brand (Mitchell) and the player. it wasn't in working condition and he was selling it at quite a cheap price (all in all plus shipping about $60 SGD). it could play 33, 45 and 78rpm records and it was electric so i decided to get it mainly to play 78's because although the gramophone i have could play 78's, its heavy tonearm would eventually ruin the records after many plays. this player had an inbuilt loudspeaker and would be ideal for listening to 78's (especially the more modern non-acoustically recorded ones).

i tried for many days to search online for this brand of player as well as the specific model, Mitchell Model 1265, but to no avail. there were no examples of it anywhere and those that i emailed had never heard of this model before. it comes in a plain suitcase form as shown below:

when it arrived, i realized that i had made quite a big mistake. the player was made to be played in the USA and accepted only 120V mains supply at 60Hz whereas where i am (Singapore), it is 240V at 50Hz. while i could easily get a transformer to convert 240V to 120V, the difference in mains frequency meant that the motor of the player would not spin at the correct speed. the player also emitted a loud hum when i turned it on, and when i attempted to touch the tonearm i got a good shock from it.

i put the player into the corner of my room and never touched it for a few months while i occasionally went online to search for any other examples of the player and the brand (none at all, if you were wondering).

a few months ago i did take the player apart and took a good look at its innards...and it was a mess...and unfortunately at that time my compact camera that i had always used to take the pictures used in this blog decided to give up the ghost and i was left with just my phone's camera to take pictures and i didn't do a good job documenting it.

it wasn't pretty...

to summarize quickly, i had to clean out the decades worth of dust and mold inside the suitcase and then replace the parts that were the most likely to have failed over the years. After taking a good look around, it was clear that the only components were the capacitors and the vacuum tube. in the picture above, i already replaced the biggest capacitor in the amplifier (the silver cylinder thing). it is actually 3 capacitors in one big cylinder with a common ground.

on the cylinder it is written:

GUDEMAN (the brand)

MEL - 42110 (the part number i guess?)

RED 40MFD 150VDC

RED 40MFD 150VDC

BLU 20MFD 25VDC

BLACK COM - NEG

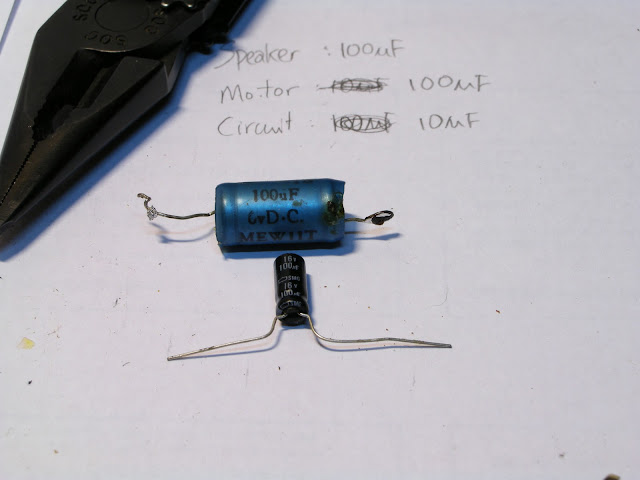

so this means that the respective wire colors are connected to capacitors of that value and voltage rating inside the cylinder. i bought two 47uF capacitors rated for 160VDC and one 22uF capacitor rated at 50VDC as replacements and soldered the connections together. you can see the difference in sizes a few decades of technology has given us:

there was another capacitor in the amplifier and it was a paper-oil capacitor with a wax coating. after researching online, it was clear that this capacitor definitely had to be replaced because paper capacitors are well known to fail from old age.

i bought a modern aluminium capacitor with the same ratings, .1MFD (100uF) and rated for 200VDC and soldered it into place.

the amplifier has one 25L6GT vacuum tube and it glows orange when the player is powered up. i know next to nothing about vacuum tubes and i didn't fiddle with it. i know enough to identify that if the tube is glowing in colors other than red-orange then it should be discarded, and also that if the top has turned a milky white instead of transparent then it should also be replaced. this one had none of the above and so i kept it in place.

the loudspeaker on the player had a small tear on the cloth (more like paper) diaphragm and i did a quick fix by sticking a small piece of paper with some light glue over the hole. i've done this before and it works well...it's enough to stop air from leaking out and the sound will still be as good as a normal diaphragm.

the main problem after all this was that the motor still doesn't spin at the correct speeds. a record player is worthless if the songs it plays are all in slo-mo, unless you intend to use it in a horror house or something...

there is a knob on the side of the turntable to select the speed of the player. when it is in the off position, the motor still runs.

as you move the knob from one setting to the other, it adjusts the position of the grey wheel shown in the picture above. the wheel touches the shaft of the motor which has three different thicknesses. this enables the speed of the grey wheel to change while the speed of the motor stays constant. (think of it as a gearing system). to make the wheel turn at a faster speed, i put different thicknesses of heat shrink tubing over the shaft to make it thicker and allow the grey wheel to turn faster.

after a few hours of trial and error, i found one type of heat shrink tubing that added enough thickness to the shaft to make it spin at 78rpm when the knob is at 78. unfortunately, i could not get the correct shaft thickness for the 33 and 45rpm speeds but 78 is good enough for me!

again, if you're wondering how to verify your record player's rpm, just use a strobe disc that can be found on the internet and print it out. i've been using the same disc to calibrate my gramophone and it has been accurate enough so far.

as my country's mains supply is 50hz, any light will flicker at that frequency and when the bars of the 50hz strobe disc at the rpm you are calibrating for seem to be stationary, then you know that you have the correct rpm.

the last thing that needed to be replaced was the cartridge. the original one that came with the player was an Astatic cartridge that had the numbers "16L3" on it.

again, there wasn't much information available about this cartridge online. i sent out emails to a few different turntable needle stores and only one had the exact same cartridge available but was selling it at $100++SGD which was insane.

i finally stumbled upon this site: http://www.needles4turntables.com/ceramic.htm and sent an email asking if it will work with my player. he replied and recommended that i get the Pfanstiehl P-51 cartridge with the 3mil needle that will work well with 78rpm records.

he shipped it out the day i made the order and it arrived in 7 days (USA to Singapore) and i proceeded to connect it to the tonearm.

the reason for the shoddy wiring you see in the picture above was because the new cartridge is a lot smaller than the old one, thus the wires could not reach the connections. i extended the wiring by splicing new wires to the old one but i didn't have wires of the same thickness, thus resulting in the frankenstein-ish work...

i turned the player on and used a toothpick to lightly brush the needle on the cartridge and there was sound coming out of the player's speaker!

i put the player back together and put on a 78 record and it came aliveeeeeeeeeeeeeeeeeeeeeeeeeeeeeeee!